First of all, I'm not some sort of a professional. I've just been watching lots of YT videos and practicing soldering at home with the tools I have.

What tools do I have? Well, my main tool is the soldering station Lukey 852D+. Not something fancy. The soldering iron in it has Hakko 936 compatible tips, so I ordered some copper tips. Yes, copper tips, the ones that get dirty and burn out over time. I just love how good the heat transfer is with copper tips.

My first microsoldering tip will be about choosing a soldering tip. You might think that a thin pointy tip will be good for microsoldering, sometimes that is the case, but I prefer the C-series tips (sometimes also called bevel tips). The trick is the angle you're holding it at. When you need to solder something big, you use the main working area of the tip, it's flat and has a big area to transfer the heat. On the other hand, when you need to solder a tiny wire, you can angle it in a way that only a tiny area of the tip is touching the part.

You should also use flux, a lot of flux. Not only does it make the joints prettier and solder flow more easily, but also helps the heat transfer. When you need to touch up a very small connection, always use flux, otherwise you may leave a big ugly solder blob. The fact that flux helps with heat transfer will also let you keep the tip at a bigger distance, so you can work on small areas without affecting nearby components.

Chose a good temperature. With enough flux, leaded solder and a good soldering iron, you can keep the temperature lower. I prefer to solder at just 275 degrees Celsius. For very massive components with unleaded solder I use 295.

Don't cheap out on the solder. I know it's tempting to grab the cheapest option on aliexpress, but those usually turn into crumbly gunk when heated, making dull joints. Right now I'm using Kaina leaded solder and am very satisfied with it.

You don't need steady hands for microsoldering. I have insanely shaky hands, so shaky in fact, that I have issues taking pictures, they come up blurry a lot of the times. Work on your posture, rest your hands, so they can't shake. Get comfortable with the soldering iron being close to your fingers, as that will also help you hold it better. Just be careful :^)

Patience is important. It's ok to take breaks when you can't do something. Stress only makes you more clumsy, so try to relax.

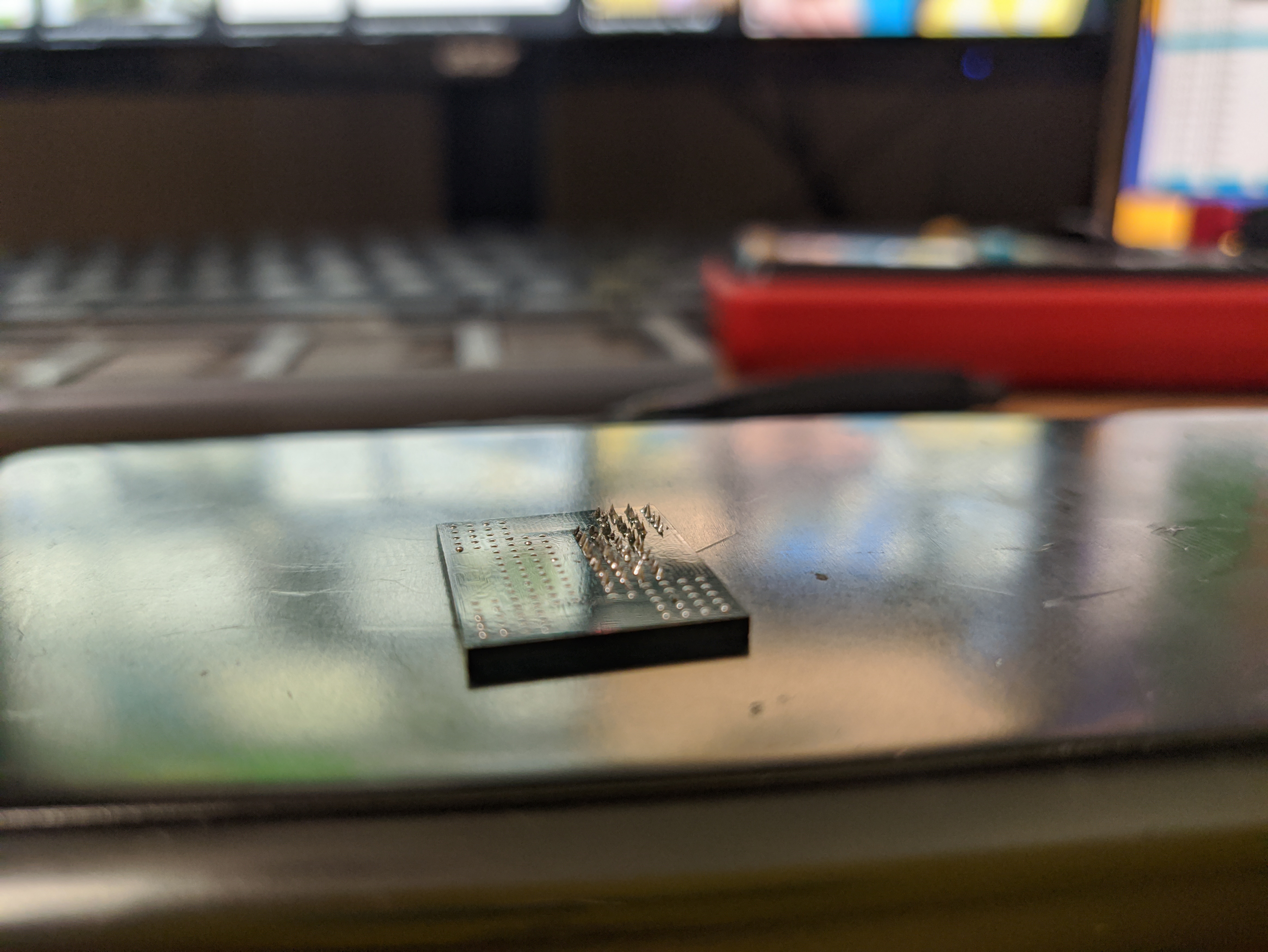

A lot of things will come with experience. I didn't think I could solder a BGA chip until I tried a few times, and it finally worked. Fun thing, I don't even have a stencil and paste/solder balls. There is a silly method to reball a chip with just the soldering iron I found on YT. Obviously, it'll only work on chips with bigger ball pitch (>=0.4mm).

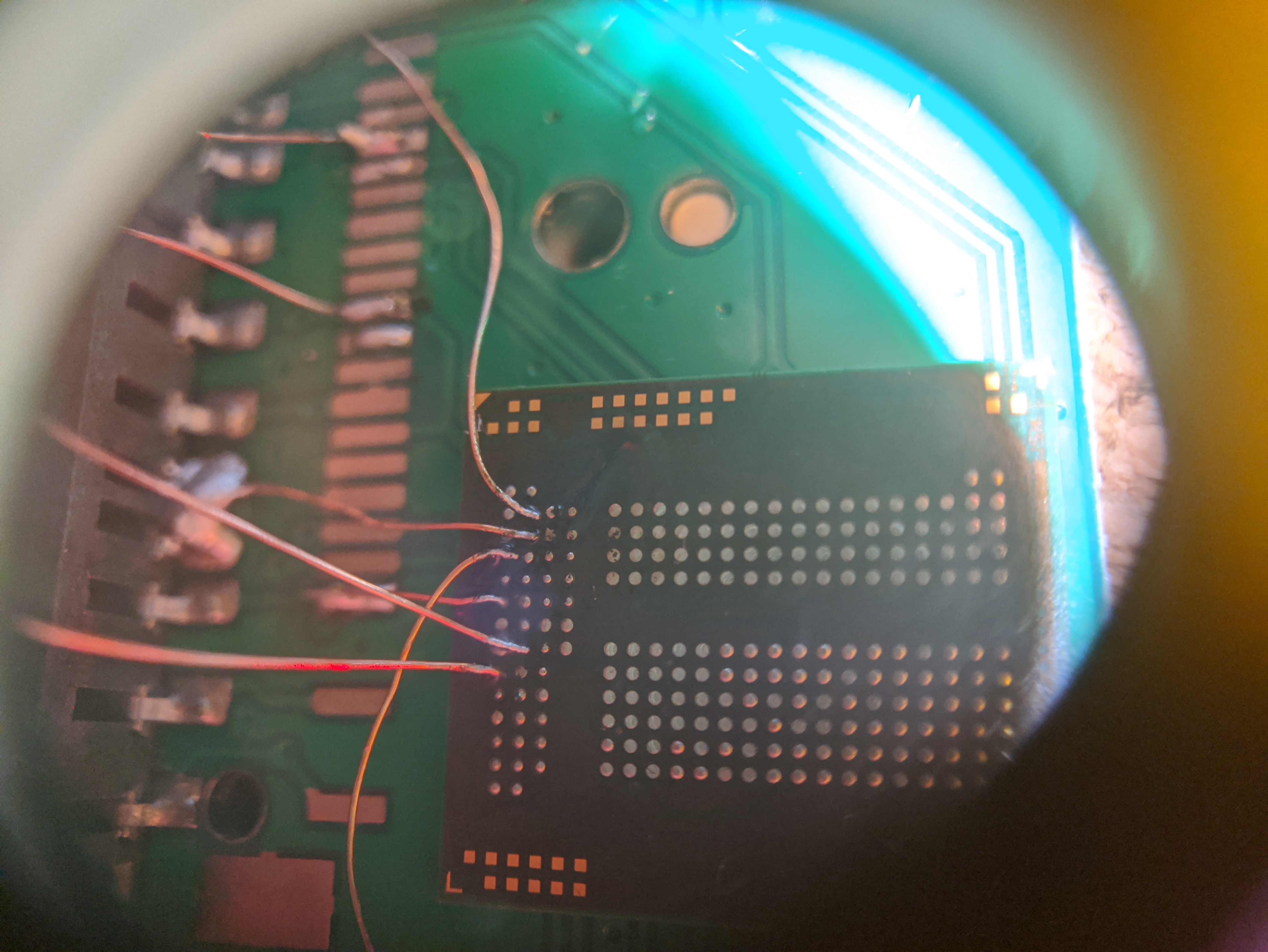

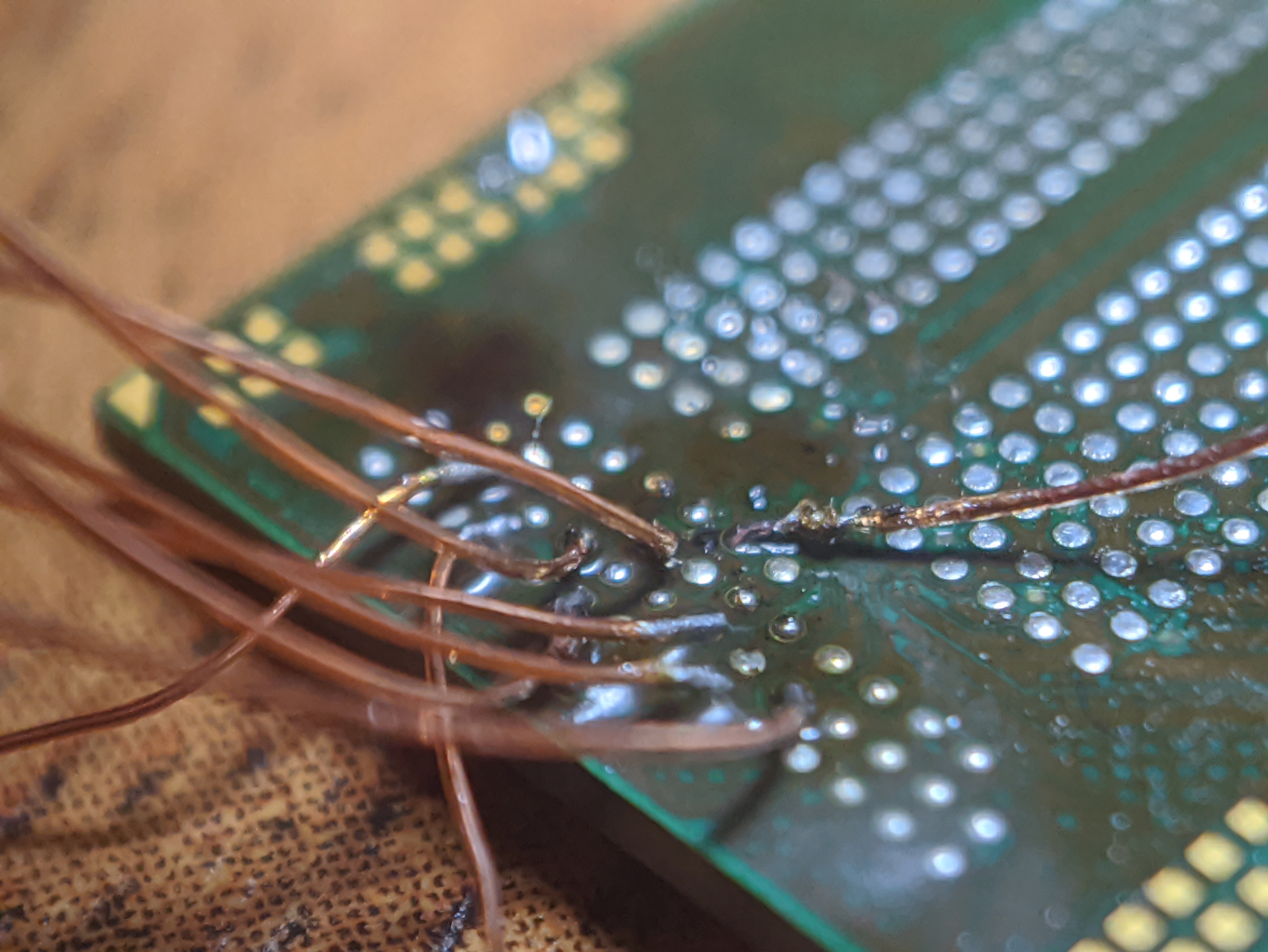

Basically, you clean up the chip, wipe off all the flux and take a small solder blob on the tip of your iron. Without the flux the solder will make the solder spikes when you pull away the tip after touching the pad. It takes some patience, but is a viable option in some cases. After making the spikes on all pads roughly the same size, you add flux and reflow them into solder blobs. The final result looks quite decent and actually worked in the end.

Here are some examples to show you the things you can do even with a bigger tip. I wanted to try and solder some wires to an eMMC chip, to get the data on it. The chip has the BGA221 footprint.

It was quite hard, and I did have to solder a few wires multiple times, but I got all the necessary pins connected properly without shorts in the end.

So I hope this will motivate you to keep trying! You don't need some fancy equipment to practice and make you more skillful. Obviously, fancy equipment makes some things easier, but that should never stop you from trying, it all comes with practice :^)

0 Comments latest

No comments.